Success stories

Biscuits and cookies are universally popular and the global market outlook is promising. Global trends like health and well-being on the one hand and indulgence (to make oneself feel better) on the other hand force biscuit manufacturers to shorter innovation cycles and as a result, increased process complexity. Efficient material handling solutions and intelligent automation are becoming prerequisites for success, as illustrated in the case of a leading Dutch cookie manufacturer.

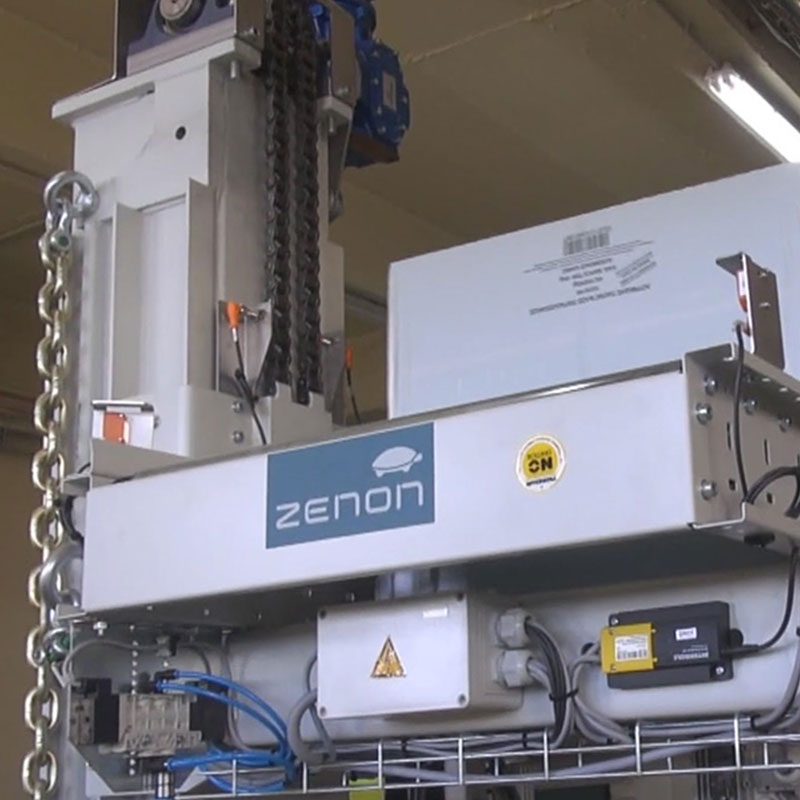

Zenon Automation SAICT, a leading Greek supplier of integrated robotic and automation solutions, successfully completed the installation of a fully automated handling and palletizing system for three carton packaging lines for Nestlé Hellas S.A.

Wholly-owned by pharmaceutical companies, the COFARES Group is a distribution cooperative for drugs and medical devices. It is the leading pharmaceutical distribution company in Spain. With a turnover of more than 2.523 millions euros in 2014, the company operates nationwide in Spain.

A global bakery supplier of liquid glaze and frosting was inconsistently filling 3 and 5 gallon pails of product. Because of variability in the product flow as plant temperatures increased after start up, the time-fill machine was overfilling the buckets by as much as 5% to ensure that minimum specification weights were met.

AP Dataweigh Inc. designed a checkweigher, label detection and lid detection system that solved all of the above issues.