News from the ROI world

January 07, 2026

Viscon introduces the Kameleon – automation that adapts

Agility meets innovation with this innovative 3-in-1 system that detects, opens, and inspects folding crates in a single compact module.

December 19, 2025

FPT Robotics masters heavy-duty automation

A major European production site recently introduced a new powerhouse to its warehouse operations – a two-meter high, 3.3-ton robotic system to automate the handling of full carton layers.

December 10, 2025

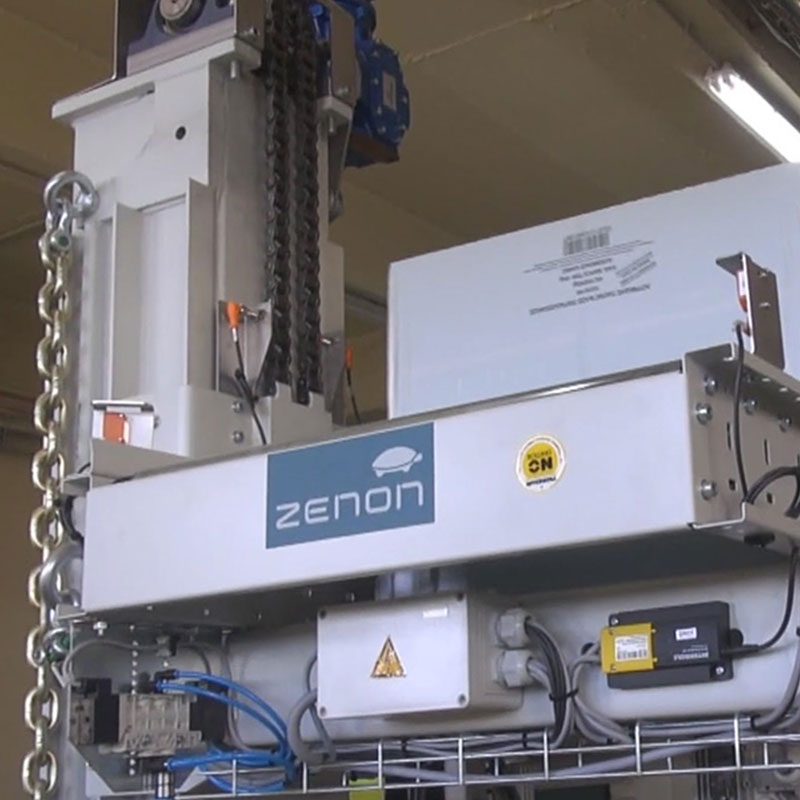

Zenon's 4-lane channelizer sorts out sausages

For a major deli meat producer, the ROI partner engineered a customized channelizer that automatically sorts, orients, and spaces products from multiple lines, ensuring perfect positioning before labeling.